Height measurement of an incomplete filling and a crater depth

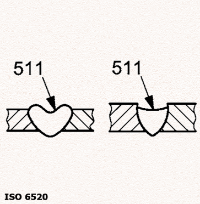

Incomplete filling - It’s a continuous or an intermittent longitudinal groove on the surface of the weld formed due to insufficient filler material

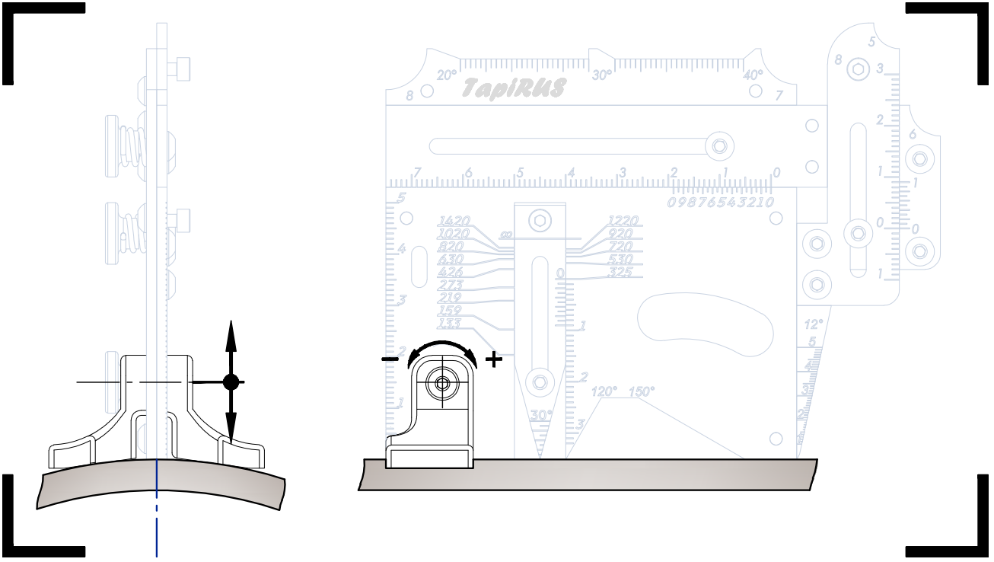

positioning the welding gauge

- Position the welding gauge on the lower part of the weld, perpendicular to the weld and close to the fusion line.

- For greater stability of the welding gauge during measurement taking , use the pivots.

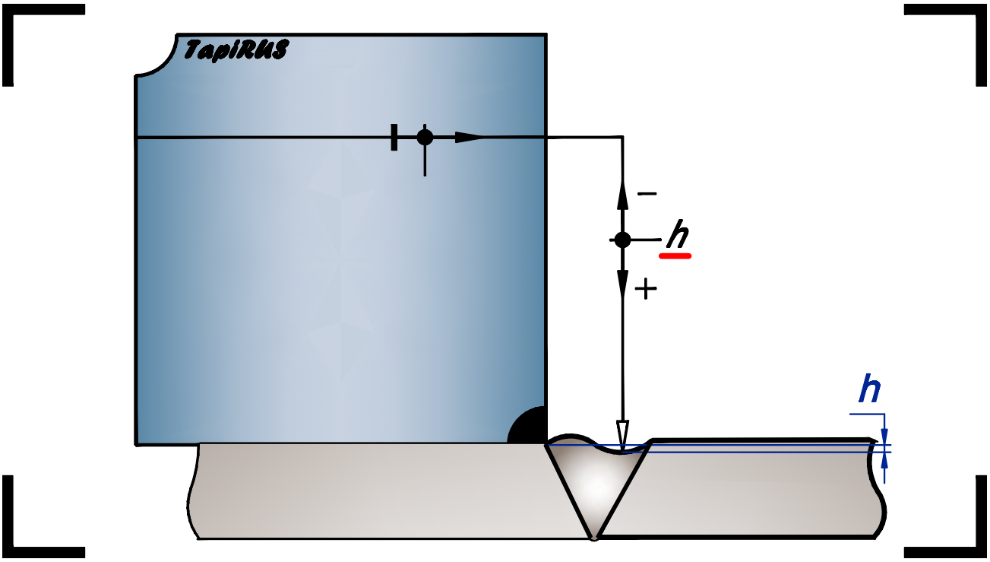

˟ the parameter measured during monitoring process is highlighted in red

measurement taking

- Adjust the linear member 3 so that the taper gauge 5 is above the point of measurement (at the point of greatest concavity).

- Lower the top High-Lo arm 4 so that the taper gauge 5 makes contact with the surface of the test object at the point of measurement.

- Take the value of the desired parameter h from the vertical scale H.